Rebar Straightening & Cut-off Machine adopts CNC preset curing block, make the steel bar straightening, bar cutting work is more reliable and flexible, and according to the actual needs, without changing the hardware conditions at any time convenient to change the program, to complete the control of the production process and the technological process.

It is mainly applicable to cement prefabricated factory, cement factory, construction site, highway, railway, bridge building, steel market, etc. After the round steel bar reinforced straightening and cutting machine, the surface of the reinforced bar is basically unscratched, the strength loss is small, the straightness is easy to operate, and the adjustment is convenient.

|  |

Parameter of Steel Wire Rod Straightening And Cutting Off Machine

| Product name | GT4-14 rebar straightening and cutting machine |

| Working speed | 0-100m/min |

| Motor power | 20.5KW |

| Machine size | 2345*700*1160mm |

| Total weight | 1000kg |

| Working diameter | 4-14mm |

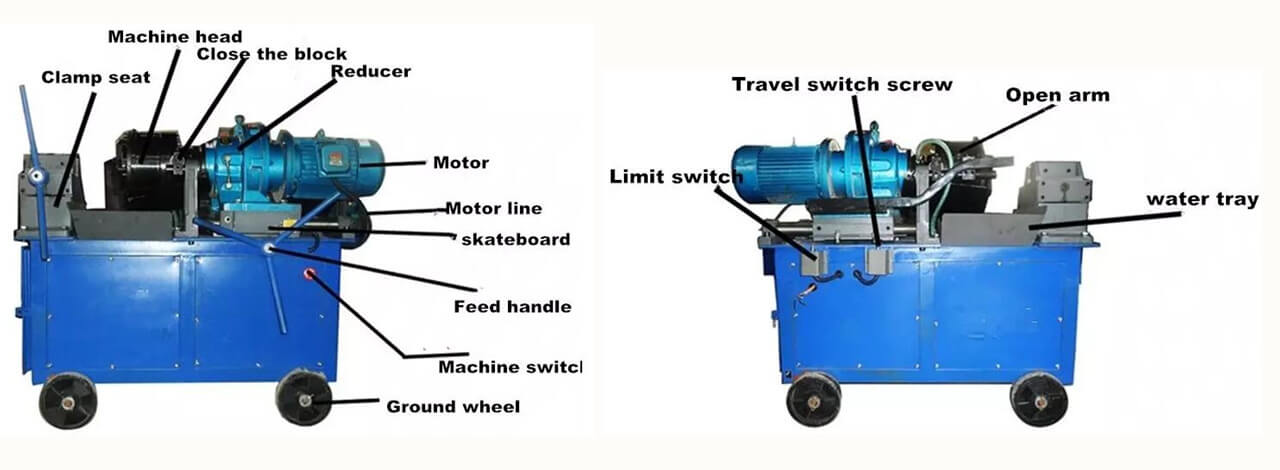

Rebar Thread Rolling Machine

HUACHEN Automatic rebar thread rolling machine is an upper design for steel rebar processing machine in the construction industry. It quickly and directly rolls the end portion of the steel bar to make the wire head part cold-hardened, so that the strength is improved, and the steel wire head is made the same as the base material. The machine consists of a frame, clamping mechanism, feed carriage, reducer and thread rolling head, cooling system, and electrical system.

Rebar thread rolling machine is mainly applied to peel rebar rib first, then roll parallel thread on rebar end, after that, two threaded rebar sectors could be connected by coupler. It is a necessary machine for rebar joint.In addition, it is also applied to roll threads on round steel bar, anchor rod, or other equivalent materials.

| Technical Parameter of Rebar Thread Rolling Machine | |

| Model | HGS-40 |

| Rebar diameter | 14-40mm |

| Max.process length | 80mm |

| Work schedule | 80mm |

| Speed | 62-80r/min |

| Motor power | 4KW |

| Voltage | 380V |

| Efficiency | 30-40mm/min |

| Dimension | 1500*600*1000mm |

| Weight | 450kg |

The concrete mixer comprises a power mechanism connected by a shaft and a transmission mechanism and a drum driven by the transmission mechanism, and a ring gear disposed around the drum cylinder is mounted on the drum cylinder, and a gear meshing with the ring gear is disposed on the transmission shaft. The utility model has the advantages of simple and reasonable structure, and the gear and the ring gear are meshed, which can effectively overcome the slip phenomenon between the roller and the mixer drum in the rain and fog weather; the adopted transmission mechanism can further ensure the elimination between the roller and the mixer roller The phenomenon of slipping.

Technical Parameter of Concrete Mixers

| Model | JZC250-DR | JZC350-DR | JZC500 | |

| Work performance | Discharge capacity(L) | 250 | 350 | 500 |

| Discharge capacity(L) | 400 | 560 | 800 | |

| Productivity ( m³/h) | 6-8 | 10-14 | 18-20 | |

| Rotating speed of mixing drum ( r/min) | 14 | 14 | 14 | |

| Aggregate size ( mm) | 60-80 | 60-80 | 60-80 | |

| Water supply accuracy | error≤2% | error≤2% | error≤2% | |

| Diesel engine parameters | 10p | 15p | 15p | |

| Tire specifications | 6.50-16 | 6.50-16 | 6.50-16 | |

| Packing size (length * width * height)mm | 2200*1900*2580 | 2600*1950*2580 | 3300*2100*2580 | |

| Weight | 1200kg | 1350kg | 1780kg | |

Secondary constructional column pump is the smallest concrete pump in China.This pump is mainly aimed at some special construction projects or narrow space construction conditions due to the size of the equipment caused by the construction of inconvenient or difficult to complete the construction schedule and carefully designed high-tech products.

Technical Parameter of Concrete Pump

| Item | HC-15 | HC-30 | HC-37 | HC-40 |

| Motor power | 15KW | 30KW | 37KW | 45KW |

| Aggregate size | 0.5cm | 0.5-1.0cm/1-2cm/1-3cm | 0.5/2/3cm | 0.5-1.0cm/1-2cm/1-3cm/2-4cm |

| Vertical conveying distance | 15-20m | 60/25/15m | 80/40/25m | 120/70/40/20m |

| Horizontal conveying distance | 50m | 100/80/60m | 150/100/80m | 200/150/100/60m |

| Theoretical conveying capacity | 3-4m³ | 12-15m³ | 15-18m³ | 20-25m³ |

| Hydraulic system form | Remote control, electric control form | |||

| Hydraulic oil cooling | Air cooling | |||

| Dimensions | 1850*750*1100mm | 3250*1450*1550mm | 3580*1500*1580mm | 3980*1500*1580mm |

| Machine weight | 600kg | 1500kg | 1800kg | 2500kg |

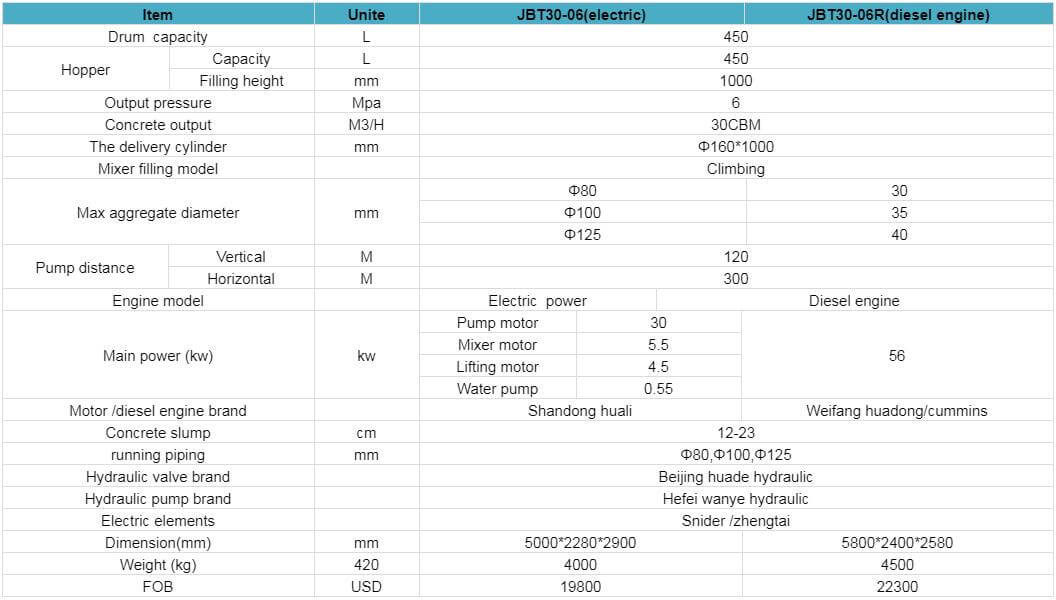

The concrete mixer pump, is a traditional concrete mixers and concrete pumps together, to achieve full concrete construction process automation material, mixing, pumping in one of the small high pressure concrete pump, suitable for small and medium sized, ground transportation, such as playing a large village aggregate concrete, especially for a group of 12 layer floor, small bridges, wild place scattered site mixing of concrete construction projects. The product can be achieved without human or trailer transitions, greatly improved work efficiency.

The concrete mixers pump machine is suitable for the transportation of large aggregate concrete such as foundation pile driving, including: rural civil construction, township and new rural construction, road and railway tunnel construction in various caves; water conservancy and hydropower engineering; geological disaster slope treatment; irrigation and other basic concrete pouring large or narrow space and other construction features.

|

|

Technical Parameter of Concrete Mixers with Pump

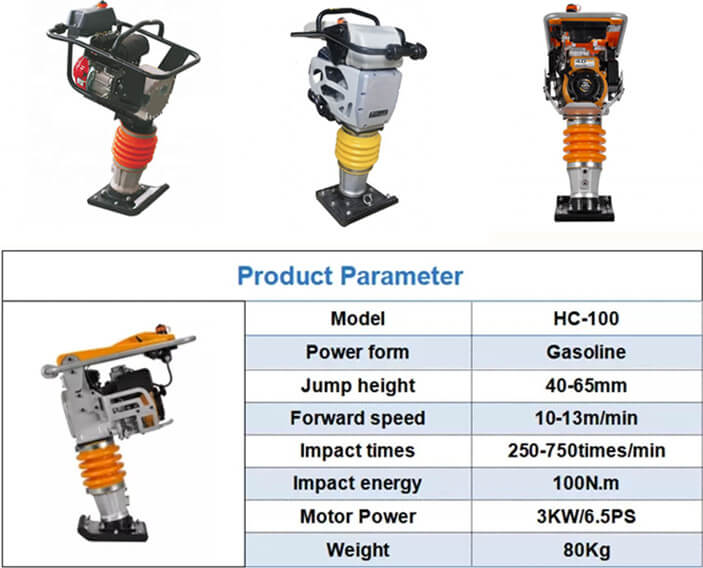

Tamping Rammer & Plate Compactor

Gasoline impact rammer application in building, ground, courtyard, roadbed, bridge pile, grooves, the wild, narrow site environment construction can be competent for large and medium-sized machinery to complete the construction task. Can be used for highway construction of the Taiwan back backfill gravel compaction, municipal, airport, port, station of road foundation soil compaction underground waterways, underground electrical pipeline, gas pipeline peripheral back fill compaction and narrow site construction.

Vibration plate compaction is mainly suitable for the bonding force between compacted particles and less friction materials, such as river sand, gravel and asphalt. The main working parameters of vibrating plate compaction are: the surface area of the working plate, the quality of the whole machine, the excitation force and the excitation frequency. In general, the same size of the plate floor area is similar, so the performance of the plate impact compaction is mainly affected by the quality of the whole machine, excitation force and excitation frequency. The excitation force is mainly used to maintain the forced vibration of the compacted material, while the excitation frequency affects the compaction efficiency and the degree of compaction, that is, under the same excitation force, the higher the excitation frequency, the higher the compaction efficiency and compactness.

If you have any questions, please contact our Executive Manager and we will get back to you as soon as possible

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.