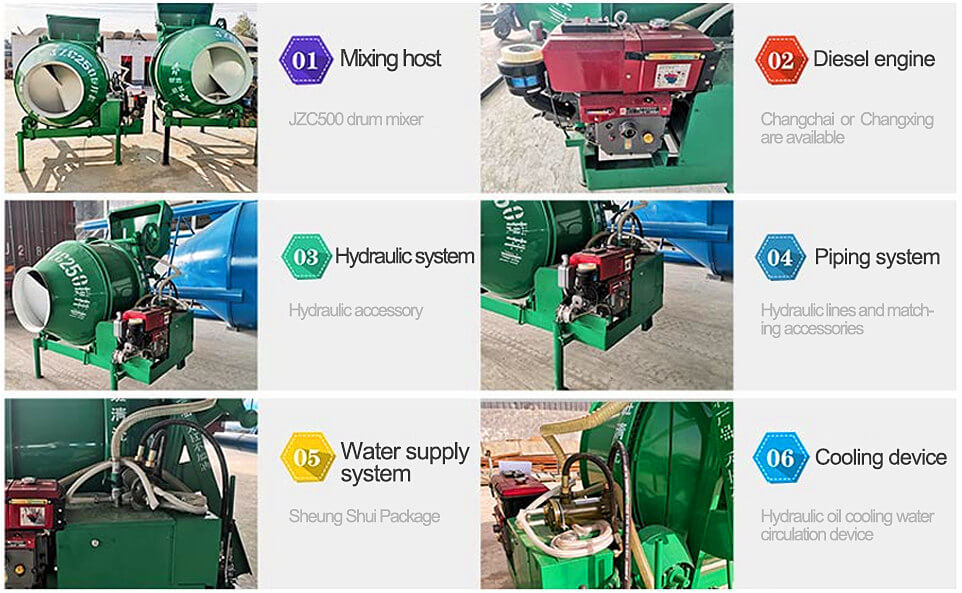

A concrete mixer is a machine that mixes cement, sand aggregate and water and mixes them into a concrete mix. It mainly consists of mixing drum, feeding and unloading mechanism, water supply system, prime mover, transmission mechanism, frame and support device.

The concrete mixer comprises a power mechanism connected by a shaft and a transmission mechanism and a drum driven by the transmission mechanism, and a ring gear disposed around the drum cylinder is mounted on the drum cylinder, and a gear meshing with the ring gear is disposed on the transmission shaft. The utility model has the advantages of simple and reasonable structure, and the gear and the ring gear are meshed, which can effectively overcome the slip phenomenon between the roller and the mixer drum in the rain and fog weather; the adopted transmission mechanism can further ensure the elimination between the roller and the mixer roller The phenomenon of slipping.

| ||||

| Model | JZC250-DR | JZC350-DR | JZC500 | |

| Work performance | Discharge capacity(L) | 250 | 350 | 500 |

| Discharge capacity(L) | 400 | 560 | 800 | |

| Productivity ( m³/h) | 6-8 | 10-14 | 18-20 | |

| Rotating speed of mixing drum ( r/min) | 14 | 14 | 14 | |

| Aggregate size ( mm) | 60-80 | 60-80 | 60-80 | |

| Water supply accuracy | error≤2% | error≤2% | error≤2% | |

| Diesel engine parameters | 10p | 15p | 15p | |

| Tire specifications | 6.50-16 | 6.50-16 | 6.50-16 | |

| Packing size (length * width * height)mm | 2200*1900*2580 | 2600*1950*2580 | 3300*2100*2580 | |

| Weight | 1200kg | 1350kg | 1780kg | |

JZC250/350/500 drum type diesel version of the concrete mixer is widely used in areas and scenes where power is underdeveloped or it is not convenient to erect power lines. The power source of the whole machine is provided by the diesel engine alone, without other additional power assistance, the power conversion eficiency is high, and the power of the machine is effectively improved.

The equipment is easy to operate, reliable in quality, stable in operation, and strong in maneuverability. It is an ideal choice for outdoor construction. The machine is equipped with a hydraulic oil cooling device after upgrade, which greatly improves the productionworking time and extends its service life.

Applicable to all kinds of medium and small prefabricated component factories and hydraulic, bridge, highway, port, dock industrial and civil construction projects, dry and hard concrete, plastic concrete, movable concrete, lightweight aggregate concrete and various mortars.

1. Q: Are you a factory or trading company?

A: We are trading company & manufacturer.specialized in concrete mixer with over 10 years rich experiences in Machinery And Equipment.

2. Q: Where is your company located? How can I visit there?

A: Our company is located in University Science Park,High-tech Development Zone, Zhengzhou city, Henanprovince. Warmly welcome to visit us.

3. Q: How long is your delivery time?

A: It is according to the model and quantity.

Generally it is 3-5 days if the machines are in stock.

It will be 15-30 days if you want to customize the machines.

4. Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer you the sample machine.

But it's not free. You need to pay for the sample and the cost of freight.

5. Q: What is your terms of payment?

A: We accept T/T, Western Union, Money Gram, Paypal, Alibaba Escrow etc.

Payment<=USD 5000, 100% in advance.

Payment>=USD 5000, 30% T/T in advance, balance before shipment.

6. Q:Besides machines,can you provide tools of machines?

A:Yes.Both machines and tools can be provided in our factory.Our company has an independent spare-part departments.If you just only need tools of your machines,we can also provide you even

if your machine is originally not from our factory.

Just tell us your needs and we can make a free design for you.

1. The spare parts and control cabinet will be loaded in wooden box.

2. The main machine is nude packing or plastic packing.

3. Also can do as customer's request.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.